Are you aware that in high-wind regions, the International Codes (I-Codes) often require the use of improved underlayment for roofing installations? These underlayments are designed to provide enhanced protection against wind-driven rain and to improve the overall durability and resilience of the roof system.

Adhering to these building codes helps to ensure that roofs in high-wind areas are better equipped to withstand severe weather conditions and reduce the risk of damage. Roofing companies operating in these regions are typically familiar with these requirements and will utilize the appropriate underlayment materials and installation techniques to meet the code regulations.

In specific scenarios, such as low-slope applications or high-wind regions, the International Building Code,® 2021 Edition and International Residential Code,® 2021 Edition necessitate the utilization of advanced underlayment materials and application techniques for asphalt shingle roof systems.

It is crucial for asphalt shingle roof system designers and installers to be aware of these requirements for improvements, and some key points are outlined below.

Roofing Companies Low-slope applications

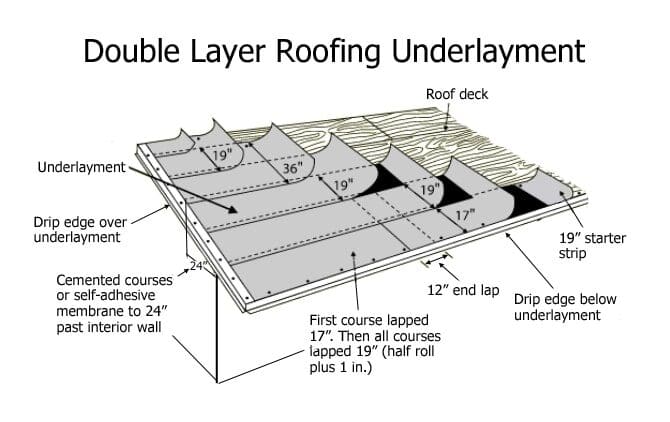

To comply with IBC 2021 and IRC 2021 regulations, asphalt shingle roofing companies with slopes ranging from 2:12 to 4:14 must undergo a two-layer underlayment process. The underlayment should be applied in a 19-inch-wide starter, parallel to and beginning along the eaves. Following this, full-width underlayment rolls should be applied in a shingle-like fashion, commencing at the eaves and overlapping successive sheets by 19 inches. End laps must have a minimum length of 4 inches and be offset by at least 6 feet.

Areas with high wind speeds.

According to the International Building Code (IBC) 2021, areas where the basic design wind speed is 140 mph or more are classified as high-wind regions. These regions have a higher risk of severe wind events and require specific considerations in the design and installation of roofing systems. Roofing companies operating in these areas must adhere to the applicable building codes and regulations to ensure that roofs are properly designed and constructed to withstand the extreme wind forces that can occur.

By following the guidelines set forth by the IBC 2021, roofing companies can help ensure the safety and resilience of roofs in high-wind regions.These areas include the Gulf of Mexico coastline, along the Atlantic coastline for Risk Categories II, III, and IV buildings from Massachusetts to Florida, along the Alaskan coastline, and along portions of the Hawaiian coastline.

On the other hand, IRC 2021 considers residential buildings to be in a high-wind region when high-wind design applies, not IRC 2021’s prescriptive design. IRC 2021’s high-wind design applies when the ultimate design wind speed is 140 mph or more.

When installing asphalt shingle roof systems in high-wind regions, IBC 2021 and IRC 2021 require underlayment to be applied in two layers, complying with ASTM D226, Type II (No. 30); ASTM D4869, Type IV (No. 30); or ASTM D6757. The underlayment must be attached with corrosion-resistant, minimum 0.083-inch-diameter, annular ring- or deformed-shank cap nails in a grid pattern of 12 inches between side laps and 6-inch on-center spacing at side and end laps.

As an alternative to the two-layer underlayment requirement, IRC 2021 permits the use of self-adhering polymer-modified bitumen underlayment, complying with ASTM D1970. Another alternative permits the use of minimum 4-inch-wide strips of self-adhering, polymer-modified bitumen underlayment over all joints in the roof deck sheathing followed by a single layer of underlayment.

While synthetic roof underlayments do not specifically comply with IBC 2021 and IRC 2021, the upcoming IBC 2024 and IRC 2024 will accept synthetic roof underlayments that comply with ASTM D8257, according to NRCA’s code change proposals approved by the International Code Council.®

In Closing

In conclusion, understanding the requirements for underlayment in roofing companies systems is crucial for ensuring the safety and longevity of a building’s roof. Both the IBC 2021 and IRC 2021 have specific guidelines for underlayment in low-slope applications and high-wind regions. Roofing companies professionals should be aware of these guidelines and follow them closely to ensure compliance with building codes and regulations.

Additionally, while synthetic roof underlayments are not currently recognized by IBC 2021 and IRC 2021, they are expected to comply with the upcoming IBC 2024 and IRC 2024 when using ASTM D8257 compliant materials. Overall, proper installation and compliance with building codes will help ensure the safety and durability of roofing companies systems for years to come.

If you work with asphalt shingle roof systems in low-slope applications or high-wind regions, it’s important to know about the special underlayment requirements. These requirements are outlined in IBC 2021 and IRC 2021, which also provide codes for other types of roof systems. You can access online versions of these codes at codes.iccsafe.org, or purchase physical copies from shop.iccsafe.org.

To learn more about asphalt shingle roof systems, you can refer to the Asphalt Shingle Section of The NRCA Roofing Companies Manual: Steep-slope Roof Systems—2021. NRCA members can access this manual electronically for free, while hard copies can be purchased from shop.nrca.net.

Leave a Reply