In 1822, Thomas Jefferson faced high costs when roofing the University of Virginia with tinplate shingles. Dissatisfied with the price charged by a certain Mr. Broke, Jefferson fired him and built his own machine for 50 cents, which worked just as well. This incident highlights the metal shingle industry’s history of innovation and cost-cutting.

The metal shingle industry, which produces modular panels designed to resemble tiles, shakes, slate, and other roofing materials, remains a young and promising field. It is populated by inventors and innovators who believe in the superiority of metal as a roofing material, both in terms of its environmental benefits and its value to customers.

Creating a metal shingle that is easy to use, durable, weather-resistant, and affordable is a challenging task. While there have been bold entries into the industry, there have also been many companies that have exited due to their inability to overcome these challenges. Jefferson, for instance, managed to solve his cost issues but faced leakage problems and eventually replaced his metal roof with wood shingles.

Let’s take a look at the evolution of metal shingles over the past 200 years and the companies that have contributed to the industry’s current state.

The Tin Shingle Era

The era of tin shingles began with the use of copper and lead on roofs since the Middle Ages. Tinplate emerged as an affordable metal roofing material in the early 19th century, followed by the development of terneplate, which required regular maintenance but could last for many decades. During this period, metal shingles were handcrafted by skilled craftsmen and became increasingly popular by the 1850s.

In the late 19th century, stamping presses were introduced to emboss tin and terne into shingles with decorative patterns, such as diamond, fleur-de-lis, and scalloped designs. These small Victorian-era shingles were often no larger than 9×12 inches. Additionally, metal barrel tiles were manufactured.

From the 1880s to the 1920s, tin shingles gained widespread popularity due to their light weight, low maintenance, fire resistance, and affordability. They required regular painting, with red and green being the most popular colors.

Although various metal shingle companies operated across the United States, Wheeling, West Virginia, emerged as a major hub for iron roofing manufacturing. The region was home to several prominent companies, including Caldwell & Peterson, William A. List & Co., and N.A. Haldeman & Co.

While tin and terne were the primary materials used, galvanized iron and steel also became popular but did not replace their predecessors. These materials were marketed alongside other galvanized products like ceiling tiles, stove pipes, watering cans, and baking tins. Properly installed, these roofs were resilient but still resembled modified stamped ceiling tiles.

Although tin shingles remained in production, their usage declined after the 1930s due to factors such as the diversion of steel for military purposes during World War I and the emergence of inexpensive asphalt composition shingles. By the mid-20th century, asphalt shingles captured up to 90 percent of the residential market.

Aluminum Shingles

In the wake of the decline of tin shingles, aluminum shingles emerged as an alternative. Aluminum gained popularity as a building material in the 1920s due to its light weight, corrosion resistance, and formability. Initially used for siding, aluminum shingles were developed in the late 1940s by companies like Kaiser Aluminum and Reynolds Aluminum. These shingles gradually evolved from siding products and found their way into roofing applications.

Other entrepreneurs, including Joe Zappone and Nebraska inventor Richard Reinke, also contributed to the development of aluminum shingles. Zappone designed his own aluminum shingle specifically for roofing, while Reinke created a corrugated aluminum shingle.

Richard Reinke, a Nebraska inventor, developed a corrugated aluminum shingle in the 1950s. These shingles featured a wave-like pattern that provided additional strength and rigidity. Reinke’s invention gained popularity, and his company, Reinke Manufacturing Company, became a significant player in the aluminum shingle industry.

During the 1960s and 1970s, aluminum shingles continued to evolve. New manufacturing techniques allowed for the production of larger shingles with improved interlocking systems, enhancing their durability and weather resistance. Aluminum shingles gained recognition for their lightweight nature, corrosion resistance, and long lifespan.

In the 1980s, steel emerged as a viable option for metal shingles. Steel shingles offered similar advantages to aluminum but at a lower cost. They became particularly popular in commercial and industrial applications due to their strength and durability. The steel shingle market expanded with the introduction of innovative designs and coatings that enhanced their aesthetic appeal.

Modern shingles

In recent years, metal shingles have seen further advancements in design and technology. The introduction of advanced coatings and finishes has improved their resistance to fading, chipping, and corrosion. Interlocking systems have become more sophisticated, ensuring better wind resistance and watertightness. Manufacturers have also focused on replicating the look of traditional roofing materials such as slate, wood shakes, and clay tiles, giving homeowners more options when choosing a metal shingle roof.

Several companies have made significant contributions to the metal shingle industry. Some notable manufacturers include:

- Classic Metal Roofing Systems: Founded in the 1980s, Classic Metal Roofing Systems specializes in aluminum shingles and offers a wide range of styles and colors. They focus on producing energy-efficient and sustainable roofing solutions.

- Decra Roofing Systems: Decra Roofing Systems is known for its stone-coated steel shingles. These shingles combine the durability of steel with the aesthetic appeal of traditional roofing materials. Decra has a global presence and offers a variety of profiles and colors.

- Gerard Roofing Technologies: Gerard Roofing Technologies is a leading manufacturer of stone-coated steel shingles. They offer high-quality products that mimic the look of clay tiles, wood shakes, and asphalt shingles. Gerard roofs are known for their durability, low maintenance, and resistance to extreme weather conditions.

- Metro Roof Products: Metro Roof Products specializes in metal shingles made from high-quality steel. Their shingles are available in various styles, including shake, tile, and slate designs. Metro Roof Products emphasize energy efficiency and sustainability in their roofing systems.

- CertainTeed: CertainTeed, a well-established building products manufacturer, offers metal shingles as part of their roofing product lineup. Their metal shingles are made from steel and coated with a durable finish. CertainTeed focuses on delivering both aesthetics and performance in their roofing solutions.

These companies, among others, have played a significant role in advancing the metal shingle industry by introducing innovative designs, improving manufacturing processes, and creating more durable and attractive roofing options for residential and commercial customers.

As technology continues to advance, it is likely that metal shingles will continue to evolve, offering even greater durability, energy efficiency, and customization options for customers seeking long-lasting and aesthetically pleasing roofing solutions.

Are you in need of residential storm damage roofing companies services or products?

Alliance Specialty Contractor, Inc. is a GAF Certified Contractor and a Full Service, Veteran Owned, Roofing companies near you that specializes in handling Storm Damage and Insurance Claims! We are the #1 source for all your roofing needs and your full-service roofing company that specializes in Storm damage roof replacement for all properties. We offer roof financing for your roof replacement.

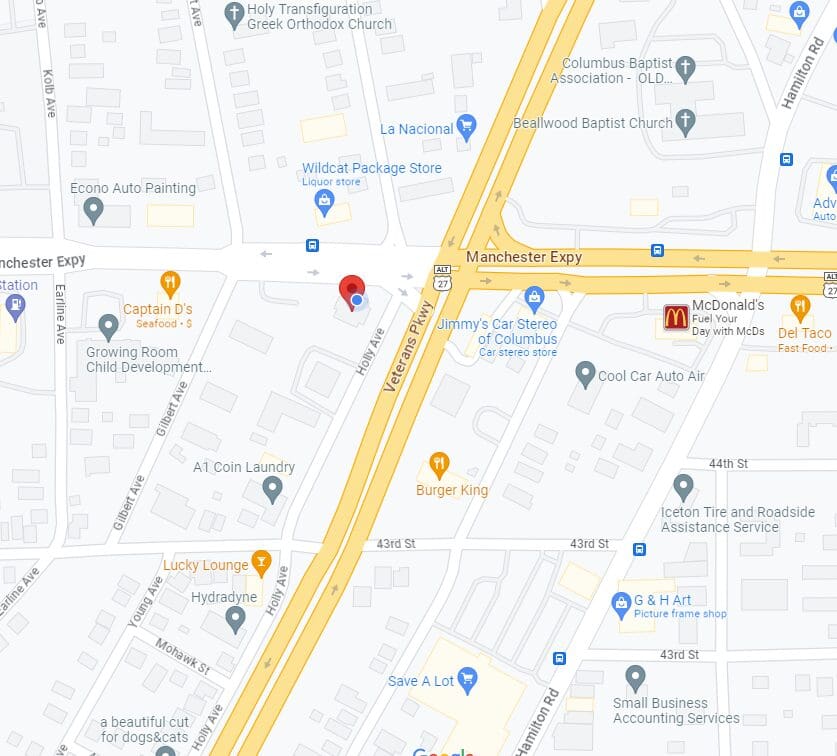

You can count on our highly skilled team to provide fast and reliable free roofing inspections. We deal directly with insurance to ensure you receive the coverage you deserve and provide the best products from GAF. Are you in the Pittsview, Seale, Salem, La Grange, Shiloh, Phenix City, Auburn, Opelika, Columbus, Midland, Ft. Mitchell, Salem, Fortson, or Smiths Station?

Contact Us Today!

(877) STORM-11

Leave a Reply